Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: Baode

Brand Name: Baode

Condition: New

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Food & Beverage Factory

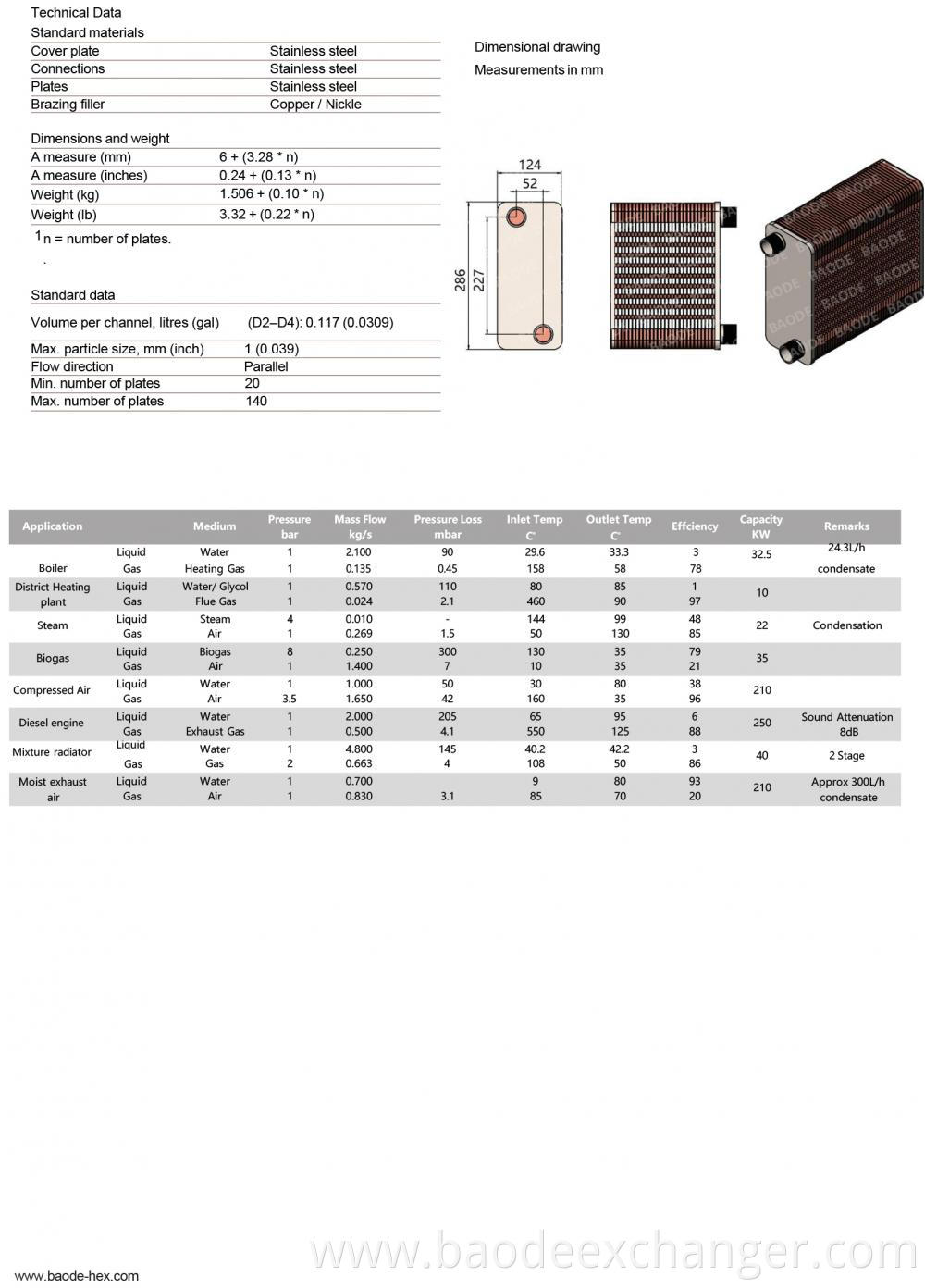

Plate Material: Stainless steel AISI316

Connections: Stainless steel AISI 316, 304

Advantage: High efficient

Application: Heating cooling

Key Selling Points: Competitive Price

Dimension(L*W*H): Customized Made

Benefits: Easy to install

Packaging: Plywood Box

Productivity: 100 Unit/Units per Month

Transportation: Express,Air,Land,Ocean,Others

Place of Origin: China

Supply Ability: 100 Unit/Units per Month

Certificate: ISO9001, CE, UL, WRAS, ROHS and etc.

HS Code: 8419500090

Port: Shanghai

Payment Type: T/T,Paypal

Incoterm: CFR,FOB,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES

Air Cross Plate Heat Exchanger for Air Cooling

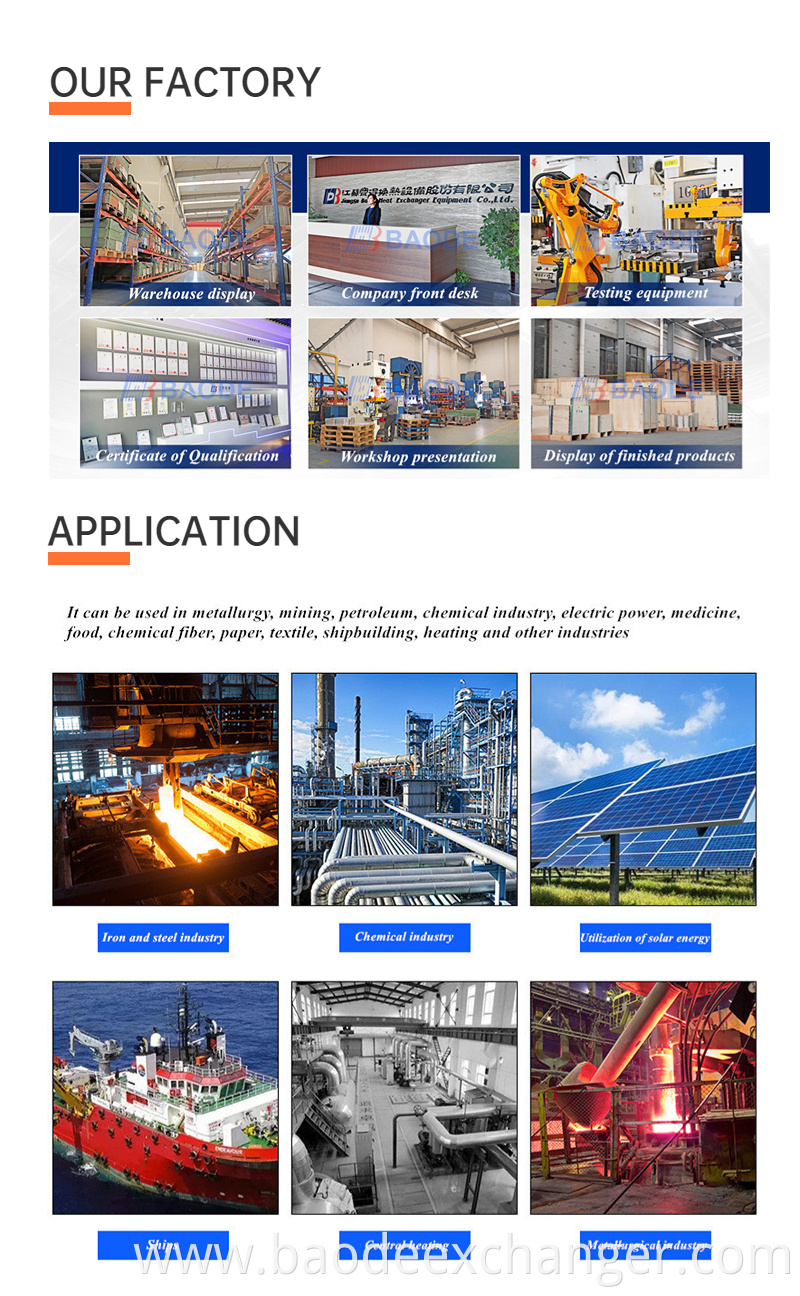

Plate heat exchangers can be widely used in:

Metallurgical industry: heating and cooling of aluminate mother liquor, cooling of sodium aluminate, lubricating oil cooling of aluminum smelting mill.

Machinery manufacturing industry: all kinds of quenching liquid cooling, cooling press, industrial mother machine lubricating oil, heating engine oil.

Food industry: salt production, sterilization and cooling of dairy products, soy sauce and vinegar, heating and cooling of animal and vegetable oils, heating and cooling of beer and wort in beer production, sugar production, gelatin concentration, sterilization and cooling, and production of sodium glutamate.

Plate heat exchanger dirt is light. This is because there is a high end flow between the plates, resulting in the suspension of the dirt mixture, then the plate as a heat transfer surface is very smooth, even if the dirt deposited on the plate, because there is no dead Angle, the surface of the plate is not easy to corrode, then the turbulence helps to wash itself, wash the dirt on the attached plate, and play a peeling role. At the same time, the flow between the plates, the space is small, the medium retention is small, so it is simple and convenient to clean.

The difference between Semi-welded Plate Heat Exchanger and Gasket Plate Heat Exchanger: one side is welded by laser welding, and there is a sealing ring above and below the interface hole; The other side is identical to the detachable side. Applications of Air Cross Heat Exchanger: Exhaust gas heat recovery.

Product Categories : Brazed Plate Heat Exchanger > Air Cross Heat Exchanger

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.