Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: Baode

Key Selling Points: Competitive Price

Material: SS304/SS316

Maximum Working Pressure: 3.0MPa

Working Temperature Range: -50 to 250 C

Heat Exchanger Type: Full welded heat exchanger

Applicable Industries: Manufacturing Plant, Food & Beverage Factory, Energy & Mining, Other

Structure: Plate Heat Exchanger

Core Components: Pressure vessel

Warranty: 1 Year

Condition: New

Packaging: Plywood case

Productivity: 500 Unit/Units per Month

Transportation: Ocean,Express,Air,Land

Place of Origin: China

Supply Ability: 500 Unit/Units per Month

Certificate: ISO9001, CE, UL, WRAS, ROHS and etc.

HS Code: 8419500090

Port: Shanghai

Payment Type: T/T,Paypal

Incoterm: DES,DAF,Express Delivery,DDU,DDP,DEQ,CIP,CPT,FCA,FAS,EXW,CIF,CFR,FOB

Working principles

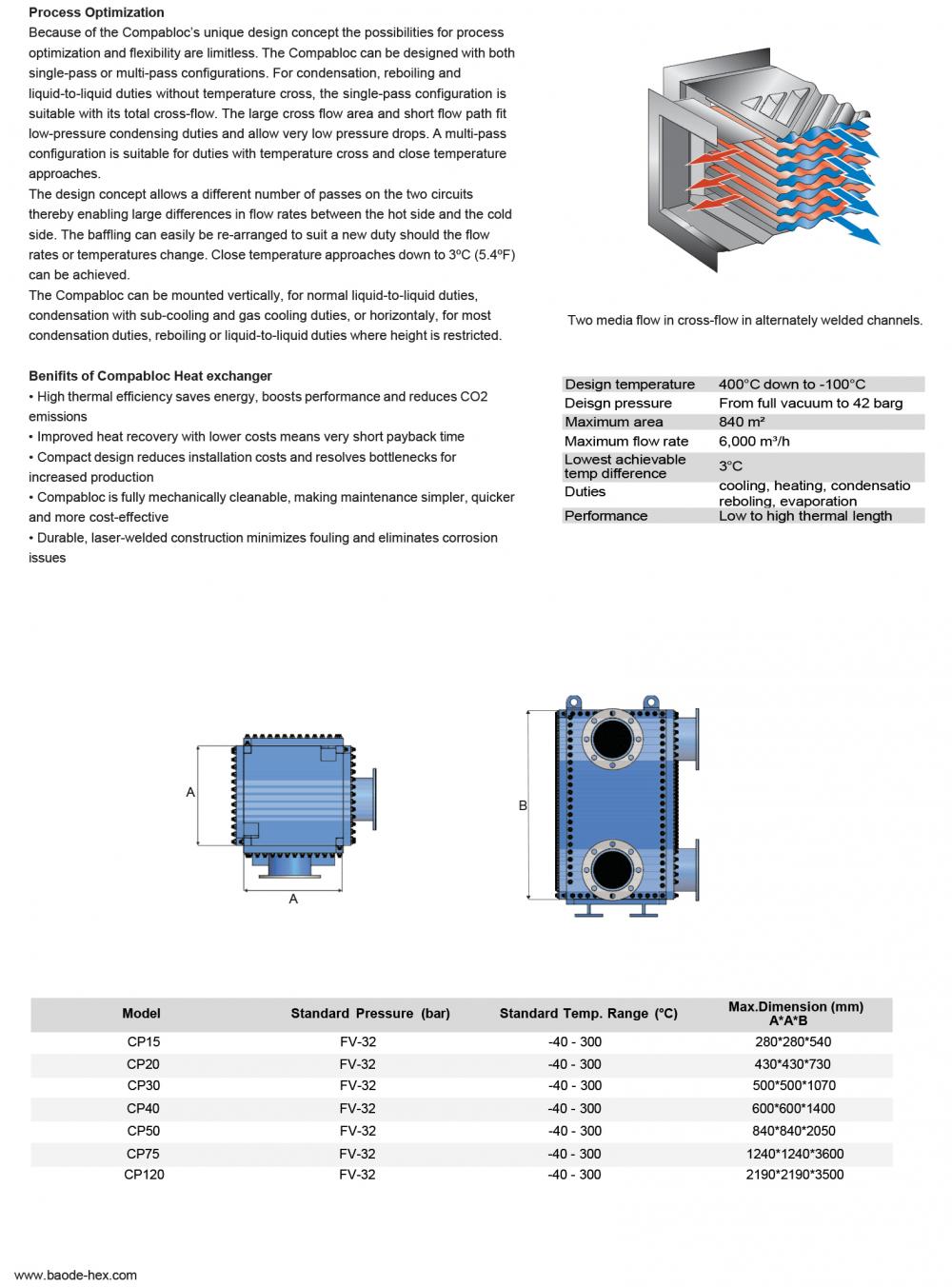

The cold and hot media flow alternately in welded channels between the plates. Each medium flows in a cross-flow arrangement within each pass. For multi-pass unit, the media flow in countercurrent. The flexible flow configuration makes both sides keeping the best thermal efficiency. And the flow configuration can be rearranged to fit the change of the flow rate or temperature in the new duty.

Advantages

The frame can be disassembled for repair and cleaning;

Compact structure , high thermal efficient and small footprint;

The butt welding of plates avoid risk of crevice corrosion;

A variety of flow form meets all kinds of complex heat transfer process.

Short flow path fit low-pressure condensing duty and allow very low pressure drop.

Plate heat exchanger is an ideal equipment for heat exchange between liquid and steam. The utility model has the advantages of high heat exchange efficiency, small heat loss, compact and light structure, small floor area, wide application, long service life, etc. Under the same.

Jiangsu Baode specializes in the production of plate heat exchangers, including Brazed Plate Heat Exchanger; Gasket Plate Heat Exchanger, shell and tube heat exchangers, etc.

Product Categories : Welded Heat Exchanger > Compabloc Heat Exchanger

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.